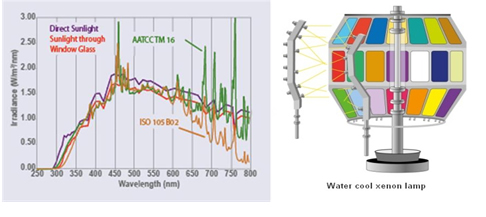

- Full Spectrum Xenon Lamp:

Xenon arc lamps give the ultimate correlation to the full spectrum of natural sunlight including UV, visible light and infrared radiation. Water-cooling makesthem economical, efficient and low maintenance. Lamps last for 2000 hours.

- Optical Filters:

A choice of optical filters is available to simulate a variety of service environments including direct sunlight and sunlight through window glass. Filter performance does not decline with age; therefore, ilters do not need to be replace dunless the glass is broken.

Three categories of optical filters are available to simulate variety of service environments.

-

Daylight Filters

Daylight filters are used to simulate direct sunlight.They provide the best correlation to natural outdoor exposures for most applications. Materials thatare typically used outdoors like roofing or exterior coatings should be tested using daylight filters.

- Window Glass Filters

Window glass filters produce spectra equivalent to sunlight coming through window glass. This spectrum can also simulate other indoor lighting suchas the harsh lighting found in a typical commercial or office environment. Window glass filters are used for indoor materials such as printing materials or textiles

- Extended UV Filters

Extended UV filters allow excess UV, below the normal cut-on of natural sunlight.They are used to produce faster or more severe test results. Extended UV filters arespecified in some automotive test methods and are sometimes used for aerospace applications

- Precision Temperature Control through Black Panel

All Q-Sun models control specimen temperature with a Black Panel ora Black Standard sensor.

Due to its black coating it absorbs all wavelength uniformly, it provides an estimate of the maximum temperature of the specimen inside the chamber.

The black panel temperature can be set anywhere between 25oC and 120oC depending upon the irradiance level, lamp age, ambient room temperature, black panel sensor and specific tester model.

Chamber Air Temperature can also be controlled simultaneously with Black Panel Temperature to give the ultimate control of specimen temperature.

- Water Spray

Outdoor moisture attack issimulated via a pure water spray.Two nozzles are located in thetop of the chamber. Spray canbe programmed to operate during either the dark or light cycle.

In addition to oxygenation, spray can be useful for creating thermal shock and/or mechanical erosion.

- Solar Eye Irradiance Control

The Solar Eye system constantlymonitors and controls lamp outputto assure precise light exposureand to maximize repeatability and reproducibility of test results.Irradiance control is available at 340 nm, 420 nm or TUV.

Operating Principle:

- Select the desired irradiance level.

- The built in solar eye irradiance sensor measures the light intensity and transmits it to the controller.

- The solar eye irradiance controller compares the actual measurement irradiance to the set irradiance point.

- The solar eye controller adjusts the power to the lamp to maintain self-point irradiance.

- Relative Humidity Contro:Available with precise control of relativehumidity. These may be usefulfor testing interior materials liketextiles, papers and inks.

- Microprocessor based controls.

- Colour touch panel.

- HMI+PLC in one unit

- Door open and Door close alarm system.

- Inbuilt calibration system.

- Separate Inbuilt printer for printing graphs (optional).

- Less use of Electrical and Mechanical Components on the Top and Bottom of Chamber - Provides easy maintenance of chamber, increases durability because of proper air circulation; cooling systems kept at bottom of the chamber to provide proper environment for compressor.

- Heated Vewing Window - Heated viewing window allows viewing fog generated and proper viewing of the test sample.

- Circulation Fan with Variable Speed -

- Electrical efficiency

Variable speed motor saves money by reducing energy bills, as it consumes less electricity than conventional motor.

- Cooling Efficiency

Variable speed enables gaining air conditioning efficiency or SEER.

- Air Quality

Variable speed motor helps clean the air efficiently. When the fan is in constant operation (indicated by the "Fan" setting on thermostat), the motor continues to slowly circulate air, allowing filters to capture more contaminants.

- Humidity Control

Variable speed motor combined with a Thermostat allows controlling the amount of humidity.

- Quieter Operation

Variable speed blower motor are significantly quieter thanits single-speed counterpart.

- Air Cooled Refrigerated System - Air cooled refrigeration system offer various benefits like

- low fan power consumption

- resistant to corrosion and freezing conditions

- requires very low maintenance

- Guaranteed long life operation

- PCRC sheet body - Powder coated steel body assures corrosion resistant chamber and allows working of chamber at high temperature applications.

- Digital Output – Target and Performance Output of the chamber operations are in digital format(digits) giving precise reading.

- Pre - Attached Data Logger with Data Analysis Software - Primary benefits of using data loggers is to automatically collect data 24-hour basis.Graph and table format of results can be produced automatically by the data logging software.

- Self - Calibration System - WEIBER incorporate a self-calibration system, in each chamber,that is completely automatic to prevent errors that could result from failure to calibrate. The system continuously monitors the environment, sensing changes that could affect analysis, and re-calibrates accordingly using a built-in long-life calibrator The process takes just a few seconds, without operator intervention or additional supplies, quickly optimizing system parameters for the current conditions.

- Open and Close Updates Through Mobile Network - Mobile technology has the potential to make services more flexible and keep informed, information anywhere at any time from mobile device, and can set alert system to know whether or not the chamber is being used.

- Reliable – Construction, performance mechanism, controls and information system integration makes the equipment reliable.

- Precise Control of Environmental Parameters - The set/ programmable parameters of the chamber are precise or have less deviation from original value,thus ensuring correct measurement.

- Micro - Processor Based Controller – Microprocessor based controller enablesprecise control of temperature, humidity, pressure and other values. Benefits:

- Processing speed is high

- Provides flexibility to alter the system by changing software.

- Compact in size.

- Operation and maintenance easier.

- Maintain precise values

- Aesthetically Designed - Designed according to the standards and principles underlining industry’s aesthetic values.

- Corrosion Resistant Interior and Exteriors - Corrosion resistant coatings like epoy coatings are applied inside and outside the chamber to prevent against degradation due to moisture, salt spray, oxidation or exposure to a variety of environmental or industrial chemicals/ corrosive agents.

- Energy Efficient – WEIBER chamber uses less energy to provide the same level of performance, comfort and convenience, thus making it energy conserving chamber.

- CFC- Free Cooling - The air cooled refrigerator use CFC (chlorofluorocarbon)-free refrigerants those are ozone friendly and eco-friendly.

- Sturdy Construction - WEIBER chambers are built with robustness to withstand stress and strain, giving the chamber long life and ability to perform in extreme stress environments.

- Low Maintenance - WEIBER systems benefit inretaining proper functionality over long period of time.

- Light Weight: Compact and superior materials ensure the chamber be light weight

HMI+ PLC IN ONE UNIT:

Weiber provides better automatic controls for the chamber by integrating HMI and PLC together. This special feature is compelling alternative to traditional methods and provides a simplified, reduced cost control system architecture.

It works by following operating steps:

- Sensors measure the physical quantity like temperature and convert them to electrical signal

- The actuation device acts upon that electrical signal

- At HMI interface between operator and chamber occurs.

- The machine operates with the logic design controls controlled by software.

- This signal is sent to the chamber by logic control devices and the chamber operates.

Basic features of HMI+PLC:

- Processor of 1.6 GHz: High clock speed processing PLC that enables speed up processing to the functions. With 1.6GHz processing speed, the PLC system is capable of multitasking, processing of large data volume, and high performance.

- Audio Output Alarm: Audio alarm alertin case of failures in any of the component controlling functions.

- 256 MB of RAM: PLC of 256 Mega Byte memory for running programmes offers high memory space for installing of more programs

- COM Port: Com port provided for attaching RS 235/RS 485 cable.

- Increased Numbers of On - Board I/O peripherals (10-50): Maximum number of 50 I/O peripherals provided on request, to attach input and output devices to the HMI and PLC. Increased number of input and output peripherals allows adding of devices like printers, recorders, etc.,as per the need.

- Data Logging and Free Programming Software: Attached data logger with input program software provided. Through data logging software, HMI and PLC collect datathrough sensors, analyse the data and save and output the results of the collection and analysis. Examples of the types of information a data logging system can collect include temperatures, sound frequencies, vibrations, times, light intensities, electrical currents, pressure and changes in states of matter.

CoDeSys (Controller Development System) software technology

Chamber Body: Double walled cabinet with inner chamber made up of Stainless steel of grade SS 304 and outer wall of heavy gauge Mild steel sheet that is degreased and pretreated with primers for rust proofing.

Insulation: It’s a process of retardation or the reduction of heat loss or heat gain for energy conservation. Weiber xenon Chamber provides cellular insulation that is through polyurethane foam.

Cellular Insulation: Composed of air or some other gas contained within foam of stable small bubbles and formed into boards, blankets, or hollow cylinders.

Heating: Desired positive temperature is provided through stainless steel sheathed air heaters, these heaters do not affect the test specimen directly as they are placed in conditioning plenum proving indirect heat.

Air Circulation: Air circulation efficient motor fans are provided, ensuring uniform temperature throughout the chamber.

Cooling: Negative temperature is maintained through ultra-low temperature application compressor and non CFC ecofriendly R 404a refrigerant used.

DETAILED DESCRIPTION ALONG WITH SALIENT FEATURES ARE AS UNDER FOR REFRIGERATION MACHINE

CONDENSING UNIT

AIR-COOLED CONDENSOR

Air-cooled condenser is internally grooved finned copper tubes used for high heat transfer area, which not only reduce power consumption, but also bring down the condensation faster. This unit is designed. &verdigris& reduces the resistance, saves energy consumption and ensure good heat exchange.

COMPRESSOR:

- HERMETIC COMPRESSOR

Single stage Reciprocating Compressor. Give the High Efficiency compared to sealed compressors, Less Power Consumption , Accessible for repairing, low noise level, Less Vibrations, Wide Voltage Range, Designed for Extremely High Ambient ,Full warranty etc

- COOLING SYSTEM

The compressor is mounted perfectly to ensure recommended level of sound and vibration.

REFRIGERATION CONTROL

- Low and High Pressure switch of RANCO/Danfoss

Which ensures the compressor and refrigeration system when low pressure will occurs it trip off the compressor. This is the only operator friendly switch can easily reset.

- Hand Shut off Valve

Is the only Condensing Unit, which is equipped with it. This valve is used for pump down the total gas in to the condenser & receiver in the faulty condition.

- Liquid Dryer of Danfoss make

Which is equipped in the liquid line for ministration of moisture in the liquid. It will collect all the moisture in side the refrigeration line as well as gas.

- Moisture Indicator of Danfoss make

The sight glass area in the Moisture Indicator shows at a glance the condition of the refrigerant system. The moisture indicator element changes colour and indicate if the system is safely dry, or dangerously wet.

- Solenoid Valve of Castle make

In most refrigeration applications, in order to automatically control the flow of fluids in a system, it is necessary to be able to start or stop the flow in the refrigerant circuit. An electrically operated solenoid valve is usually used for this purpose. Its basic function is the same as a manually operated shutoff valve, but it can be positioned in remote locations, and may be conveniently controlled by simple electrical switches.

- Oil Separator of Stainless Steel 304

The oil separator intercepts the oil mixed with compressed gas and returns it into the crankcase of the compressor, thus assuring an efficient lubrication of its moving parts. Also, it improves the overall efficiency in the system.

- Suction Accumulator

Maximum Efficiency of the relief device (expansion valve) because it is supplied with sub cooled Liquid.

- Liquid Receiver

As per ASME Section VIII Division I for storage of refrigerant.

Xenon Arc Lamp:

Xenon arc lamps are to simulate full sunlight spectrum. To reproduce the presence of different environments destructive waves,it can provide the appropriate environment for simulation of scientific research, product development and quality control and acceleration tests.

The Technical Parameters:

- Power: 1.5KW

- Outer diameter: 20 mm

- Overall Length: 350 mm

- Radiation intensity: 500 ~ 1200 W / m2

- Xenon Wavelength: 290 ~ 800 nm