Ashing is a test to deduce the amount of ash forming material present in a product so as to decide its use in certain applications.Ashing is usually performed by placing the sample in furnace and destroying the combustible (organic) portion of the sample by thermal decomposition using a muffle furnace. Typical ashing temperatures are 450 to 1100 °C. Magnesium nitrate is commonly used as an ashing aid. Charring the sample prior to muffling is preferred. Charring is accomplished using an open flame.

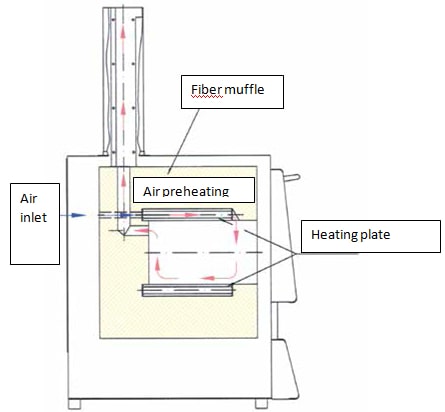

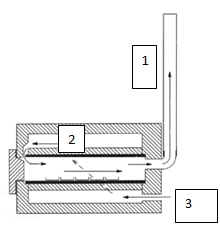

AIRFLOW IN ASHING FURNACE

- Chimney Pulls The Air Through The Chamber

- Pre heated air enters the chamber after circulating around the outside of the chamber

- Air inlet is provided.

WEIBER Ashing furnaces are Light weight with ceramic wool insulation (instead of Brick insulation). The outer casting is made of double walled thick PCRC sheet, duly painted with attractive stove enamel. The inner casing is made of ceramic wall. The unit is provided with single door (flap type, lift type, front opening). This door is provided with magnetic door closer. This door is provided with lock and key arrangement. The triple walled back of our ashing furnaces are provided with two/Four/Six/Eight (size specific) air circulation fans for uniform maintenance of the temperature throughout the furnace.

Heating:

heaters made of high grade Kanthal wires of suitable wattage.

Temperature Control:

The temperature inside our Ashing furnaceis controlled through PIDcontroller.

Temperature Range:

Temperature range of our standard furnace is 1100°C. However we have the capacity to modify the same to 1200°C tosuit the individual specialized requirements of our customers.

Air circulation:

Triple walled back of unit is fitted with air circulation fans for maintaining temperature uniformly throughout the furnace.

Features of Coaxial Circulation Fan:

- Vacuum impregnated stator winding with dr. back varnish under red baktol

- Non-hygroscopic.

- Best IR value

- Bright bar (EN - 8 class) shaft.

- Bush bearing of branded companies.

- Surge comparison testing in fans and pumps eliminates into turn short circulating of the stator.

- Pressure die-casted-rotor manufactured with zero error.

- Boats of high accuracy

Voltage:

To work on 220/230V A.C. supply.