- Chamber

The chamber is made of 304 stainless steel. It is designed and manufactured by the International standard and is checked by national technical inspection department in India The sterilizer is firm and durable.

The inner surface of the chamber is finely polished, glabrous, corrosion-proof and easy for cleaning.

The equipment has over-pressure safety device, which is safe and reliable.

- Door Structure

The sterilizer is automatic operated door structure. The door is open and closed by motors. It is made of SS304.

The door of the sterilizer is pressured-air sealed.

Double-door Structure.It has double-door safety interlocking system. When the door is not closed, then steam can not enter the chamber. When the steam pressure in the chamber is more than 0.027MPa, the door cannot open. The front door and the back door can not open at the same time.

- Pipeline System

The pipeline system is composed of the controlling valve, pipelines and the filter. It is also the energy transfusion and controlling channels of the sterilizer.

Controllimg System Controlling valve is pneumatic valve, which has the advantages of strong heat resistance performance, reliable operation and low fault rate, which will ensure the overall performance of the sterilizer.

The pipelines are connected by stainless steel pipelines. It uses hoop fitting, which is easy for installation, maintenance and inspection.

The pipeline is polished, glabrous, and easy for cleaning.

The air filter adopts sterile filter, which can prevent the second pollution of the goods.

- Controlling System

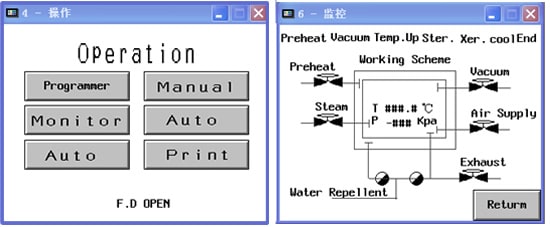

The controlling system is mainly composed of PLC from Mitsubishi. The whole system operates reliably and controls preciously, which ensure the overall performance and the sterilizing effect.

The controlling system has HMI, which has the functions including multiple sterilizing processes for users to choose, setting the sterilizing parameters, displaying the parameters and the cycle phases, printing the sterilizing reports and the compelling hand operation.

The micro printer is used for recording and printing the key parameters of time, temperature and the pressure in the operation process, which is easy for the users to file and analyze technically.

The whole system has the over current, over loading and leaking power protection system.

- Vacuum System

Vacuum system is the necessary part which is used for disposing of the cool air, keeping the temperature in the chamber evenly and ensuring the sterilizing results. It plays an important role in the process of vacuum drying clothes and dressing bag.

The vacuum system of the sterilizer is mainly composed of liquid ring vacuum pump, vacuum valve and the interconnecting pipelines. Among these, the vacuum pump is the key part. The vacuum system has good advantages of operating stably, low voice, high vacuum and quick air suction speed, which ensures the sterilizing effect and the whole performance.

- Sterilizing Programs:

The sterilizer has multiple sets of sterilizing programs:

- Mechanically Sterilizing Program:

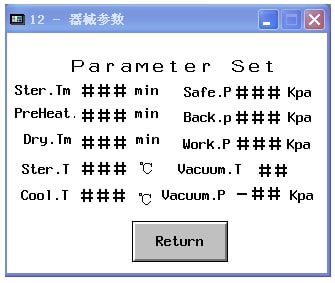

It is used for sterilizing the metal apparatus, vessels and tools. The sterilizing program is composed of pulsation vacuum, rising temperature, sterilizing (keeping the same temperature for a certain time) and cooling. The users can set the sterilizing parameters according to goods’ characteristics and manufacturing requirements. The setting range of the sterilizing parameters is: Sterilizing Pressure: 0.07-0.22Mpa; Sterilizing Temperature115-134oC, Sterilizing Time: 1-99minutes.

- Clothing Sterilizing Program:

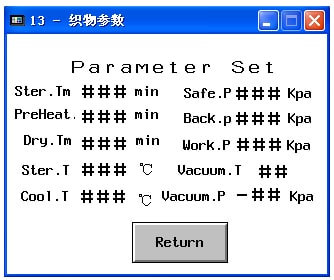

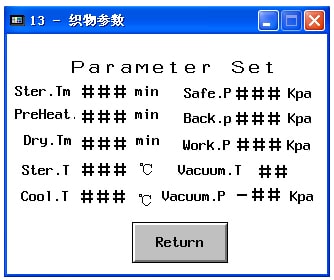

It is used for sterilizing the clothes and dressing bag. The sterilizing program is composed of pulsation vacuum, rising temperature and sterilizing (keeping the same temperature for a certain time) and drying. The users can set the sterilizing program according to the goods’ characteristics and manufacturing requirements. The setting range of the sterilizing parameters is: Sterilizing Pressure: 0.07-0.22MPa, sterilizing temperature, 115-134℃, sterilizing time 1-99minutes, drying time 1-99 minutes.

- Liquid Sterilizing Program:

It is used for sterilizing the less amount of liquid in the unsealed bottles and culture medium. The sterilizing program is composed of warming-up, rising temperature and sterilizing (keeping the same temperature for a certain time) and cooling. The users can set the sterilizing parameters according to the goods’ characteristics and the manufacturing requirements. The setting range of the sterilizing parameters is: Sterilizing Pressure: 0.07-0.22Mpa; Sterilizing Temperature: 115-134℃;Sterilizing Time: 1-99minutes.

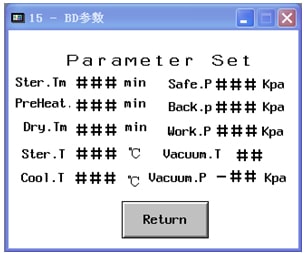

- BD-test and leakage test programs

They are used for testing the machine.

Special Sterilizing Programs can be set according to the users’ requirements.

- Loading Ways of Goods:

The goods is put into the sterilizer chamber by hands.

- Steam Generator:

The sterilizer has inbuilt electric heating steam generator, which generates the steam for sterilizing by itself.

The material of the steam generator is SS304.

- PARAMETER TABLE